Tropical fruits are not only delicious when consumed fresh but can also be preserved through dehydration, creating natural and healthy snacks. Dehydrating tropical fruits allows you to savor their vibrant flavors and enjoy them all year round. In this article, let’s discuss the art of dehydrating tropical fruits, from the initial preparation steps to specific dehydration techniques for popular fruits like bananas, mango, papaya, pineapple, and more. Also, explore the benefits of dried fruit snacks as a wholesome alternative and touch upon the packaging requirements for preserving their quality.

Initial Preparation of the Fruits Before Drying #

Before starting the dehydrating process, following specific preparation steps to ensure the best results is crucial. Begin by carefully selecting the correct ripens stage, and high-quality tropical fruits, inspect any signs of damage or spoilage, and discard the unsuitable fruits. Washing the fruits under running or bubbling water helps to remove dirt and any surface impurities. Depending on the fruit, you may need to peel off or slice it before proceeding with the drying process. Precise and uniform slicing allows for even drying and consistent results.

Blanching Practices to preserve the fruit’s color before dehydration #

Blanching, a pre-treatment step for certain fruits, can help to preserve their color, texture, and nutritional value. Hot water blanching involves briefly immersing the fruit slices in boiling or hot water, followed by rapid cooling in an ice bath or water sprinklers. Steam blanching utilizes steam to achieve the same purpose. Chemical blanching involves dipping the fruit slices in a solution containing a food-grade acid, like citric acid or ascorbic acid. We can use lemon or lime juice as a natural alternative for citric acid. Blanching can help prevent enzymatic browning, improve shelf life, and enhance the quality of dehydrated fruits.

Chemical blanching should follow the quality standards and food laws regarding concentration. As an example, the maximum allowable amount of Sodium meta-bisulfite is 1 gram for 1 kilogram of fruit. The immersing or dipping time varies according to the fruit type. Fruit containing high amounts of polyphenols need much more blanching time to deactivate enzymes.

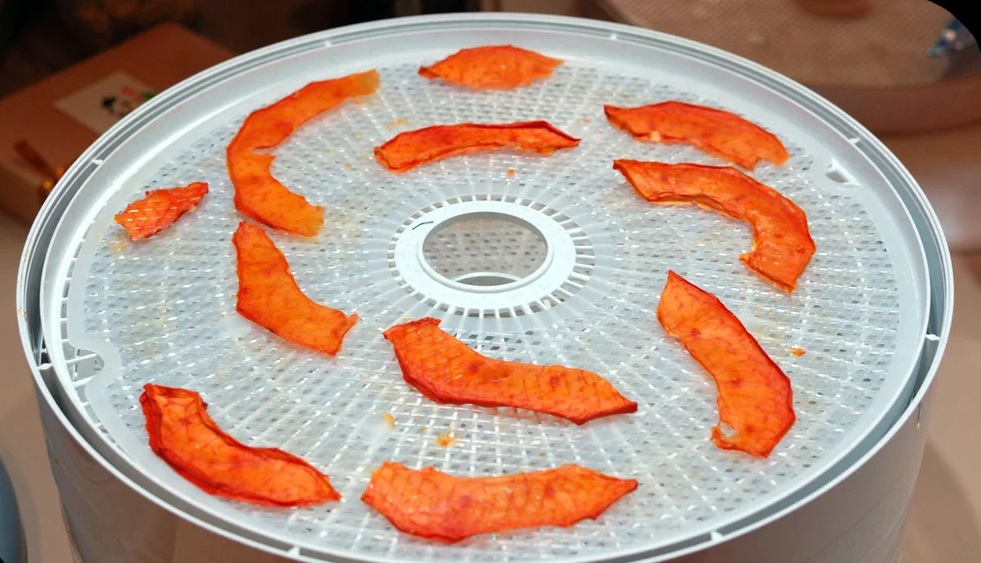

Dehydration Process of Specific Tropical Fruits #

Various tropical fruits can be successfully dehydrated to create delightful snacks. For conventional air drying, we typically use 55-60°C (131-140°F) temperatures for 8-10 hours. We should reduce the temperature and time to 40-45°C (104-113°F) for 6-8 hours in heat pump drying and obtain an excellent quality snack. Final moisture content varies from 12% to 20%, depending on the fruit type. For a leathery texture, it’s 15-20%, and for a crispy snack, it’s 12-15%. The best suitable ripening stage of tropical fruits for dehydration is between the fully matured to fully ripened stage. Normally it should be ripened with good color development and not over-ripened. Let’s explore the dehydration process for popular choices:

- Banana: Slice the bananas and pre-treat them with lemon juice to prevent browning as a natural treatment. Sodium meta-bisulfite is used to control discoloration in chemical blanching. Immerse banana slices for 2-3 minutes in 0.1% Sodium meta-bisulfite solution. Chemical blanching is more effective, but it couldn’t get an organic certificate or be marketed as a natural product. Then dry them until they become leathery or crispy, depending on consumer preference. Dehydrated banana chips are a very popular snack.

- Mango: Remove the skin and slice the mangos into thin strips or dice. Dry until they achieve a chewy, leathery texture. Citric acid or lemon juice is used for the blanching purpose, and immerse in 5 minutes. Slow, steady drying is required to get the desirable texture. Heat pump dryers and vacuum dryers are mostly used industrially. Frozen, dried mango slices are made from expensive mango varieties for the high-end export market.

- Papaya: Blanching is not required for dehydrating papaya. Peel and remove the seeds before slicing the papaya into thin strips. Then dry them until they become leathery or slightly crispy. As papaya contains more water, the most suitable method is osmotic dehydration.

- Pineapple: Pineapple is a non-climacteric fruit, and we have to consider peel color development. 75% of yellow color development in the peel is best suited for dehydration. Remove the skin, core, and eyes, then slice the pineapple into rings or chunks. Dry until they become chewy or slightly crispy. Because of its high sugar content, dehydrated pineapple is highly demanded as a tropical dehydrated snack. Blanching is not mandatory for pineapple dehydration.

- Other Tropical Fruits: Dehydration principles of fruits like guava jack fruit, citrus, watermelon, and dragon fruit use similar techniques. Jack fruit is also considered a delicious and highly demanded dehydrated tropical fruit.

Osmotic Dehydration of Tropical Fruits for Snacks and Candies #

Osmotic dehydration is another method to create unique tropical fruit snacks and candies. This process involves immersing fruit slices in a concentrated sugar syrup solution, allowing osmosis to occur. The fruit absorbs the sugar syrup, resulting in a tender, chewy texture, and infused flavors. Here, use concentrated series of sugar syrups and immerse fruits in low concentration to high concentration gradually. Osmotic dehydration is particularly suitable for fruits with higher moisture content, such as pineapple or papaya. After osmotic dehydration, the fruit can be further dried to achieve the desired texture and preserve it for longer periods. Pineapple core which is discarded during the dehydration process, can be used to make osmotically dehydrated candies.

Dried Fruits as Snacks – Are dried fruits healthy? #

Dried fruits are used to make excellent, natural snacks that are packed with nutrients and offer a satisfying sweetness. They retain the natural sugars, fiber, vitamins, and minerals present in fresh fruits. These snacks provide a convenient option for on-the-go consumption, and their long shelf life makes them ideal for stocking up. Dried fruits are a healthier alternative to processed snacks, as they lack added sugars, preservatives, and artificial flavors commonly found in commercial products. The dried fruit snacks can be naturally flavored using lemon juice and natural vanilla-like flavors.

Packaging Requirements for Dried Fruit Snacks #

Proper packaging plays a crucial role in preserving the quality and maintaining the shelf life of dried fruit snacks. Laminated films are the best packaging materials for dehydrated fruit snacks. BOPP/MCPP/PE and PET/MCPP/PE are the widely used packaging materials for dehydrated fruits. After packing, the products should keep in a cool, dark place to minimize exposure to light and heat, which can degrade the quality of the dried fruits. Adding oxygen absorbers and silica gel provides additional protection against moisture and oxidation.

Summary

Dehydrating tropical fruits opens up a world of possibilities for creating natural, healthy snacks. With careful selection, preparation, blanching practices, and appropriate drying techniques, you can transform fruits like banana, mango, papaya, pineapple, and other tropical fruits such as jack fruit, guava, watermelon, and dragon fruit into delicious and nutritious treats. Dried fruit snacks offer a wholesome alternative to processed options, retaining more nutrients, natural tastes, and flavors of the fruits. By following proper packaging techniques, you can ensure the longevity and quality of dehydrated fruit snacks, allowing you to enjoy these delightful treats whenever you desire.

Further reading

Dehydrating Fruits and Vegetables for High-Quality Export #

References

Mercer, D.G., 2014. An introduction to the dehydration and drying of fruits and vegetables. Donald G. Mercer, University of Guelph.

Mishra, S., Parth, K., Balavignesh, V., Sharma, A., Kumar, N. and Kaur, E.N., 2022. A study on the dehydration of fruits using novel drying techniques. The Pharma Innovation Journal, 11(1), pp.1071-1080.

Kumara, B.A.M.S., Hettige, K.D.T., (2020). Ripening Stage Affects the Quality of Fresh and Dehydrated Pineapples (Ananas comosus (L.) Merr.) cv. Mauritius in Sri Lanka., Journal of Sustainable Food Production, 8: 29-37pp.